1、Axial flow brief description

Axial flow control valve (flow and pressure control) is widely used in natural gas, petroleum, chemical industry, electric power, metallurgy and other industries. It is a new type of control valve with high precision. Due to the use of axial symmetrical flow passage design, it has significant structural advantages compared with traditional elbow control valves. The advantages are high precision, low flow loss, low noise, long service life, large caliber and high pressure resistance.

2、Type comparison

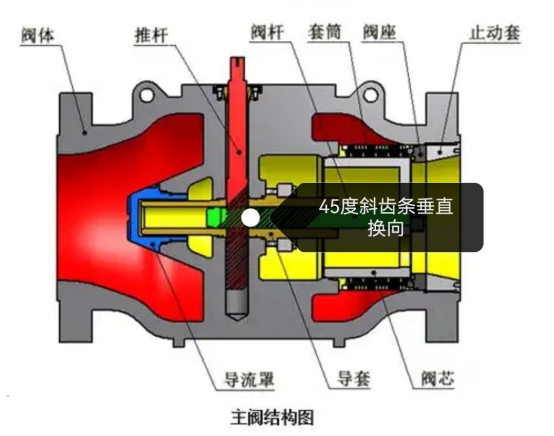

①、Existing type (45-degree oblique gear shaft vertical reversing);

Domestic axial flow control valves adopt the same oblique gear transmission structure as Mokveld in the Netherlands, which belongs to the oblique transmission, and long-distance transmission requires multi-faceted relay, and the main disadvantages of this structure (as shown in the picture below): low transmission efficiency, easy to wear, high lubrication requirements, (as shown in the gear transmission with multiple teeth in the picture), poor stability, and difficult processing.

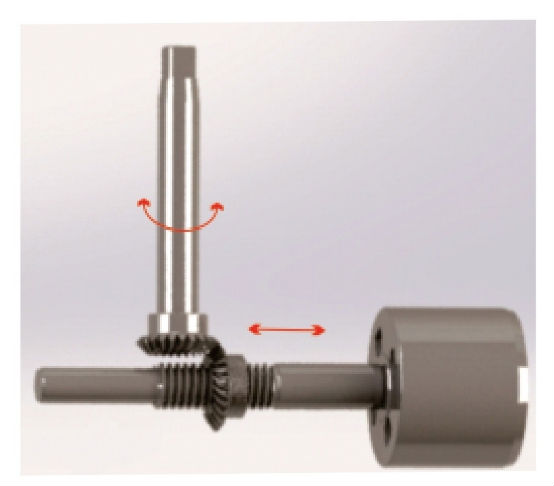

②、 Iterative type (innovative technology)

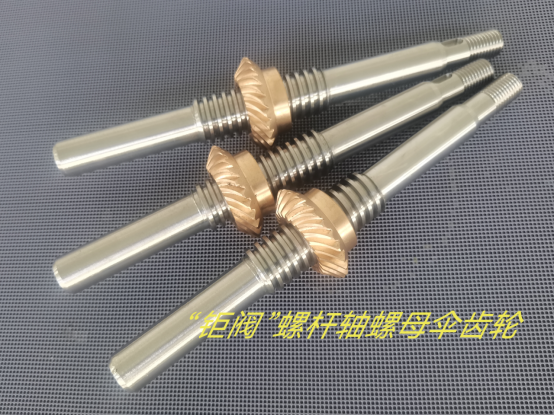

FCV-E2800 axial flow electric control valve with transmission structure of spiral bevel gear + screw nut, the transmission structure uses spiral bevel gear for direction change, one of the bevel gears has a T-shaped thread hole inner hole, which is engaged with the thread on the valve shaft, thus converting the rotation of the input shaft into the linear motion of the valve shaft (the screw nut structure is equivalent to moving the internal mechanism of the straight stroke actuator to the inside of the valve body), compared with the existing structure of the inclined surface transmission, it has significant advantages: (see the picture below)

1) Higher transmission accuracy, higher adjustment accuracy.

2) Higher transmission efficiency: The transmission efficiency of bevel gear (about 0.95) is much greater than that of 45° oblique surface transmission (about 0.50), the same specification products can be 2 levels smaller, reducing the total cost of the product.

3) Higher production efficiency: "Umbrella gear + lead screw nut" is a typical mechanical part with mature processing technology, which has stable and controllable accuracy and quality, and is interchangeable, thus naturally having high production efficiency. However, the processing of two vertical meshing 45-degree involute racks is a non-typical meshing pair of mechanical parts, and there is no ready-made mathematical processing model. Manufacturing enterprises can only rely on trial and error to accumulate data to solve the contradiction between clearance and jamming, naturally reducing production efficiency, and it is not easy to guarantee accuracy and quality stability.

3、Sealed structure ( progressive type )

The FCV-E2800 series products are all equipped with energy storage seals, which are durable and fail-proof. The main seal adopts a combined active and passive seal, meeting the high standard of zero leakage after 10,000 cycles of opening and closing.

4. Material Selection (Progressive Type)

The valve core and sleeve are made of wear-resistant stainless steel, the valve shaft is made of precipitated stainless steel, the spiral umbrella gear is made of hard tooth surface, and the T-shaped tooth surface is not only hardened but also treated with molybdenum disulfide spraying, which can cope with the severe working conditions.